Shoemaking

The Art of Shoemaking

Discover the timeless craft of handmade shoemaking, where precision, artistry, and tradition come together to create footwear that is as unique as the wearer.

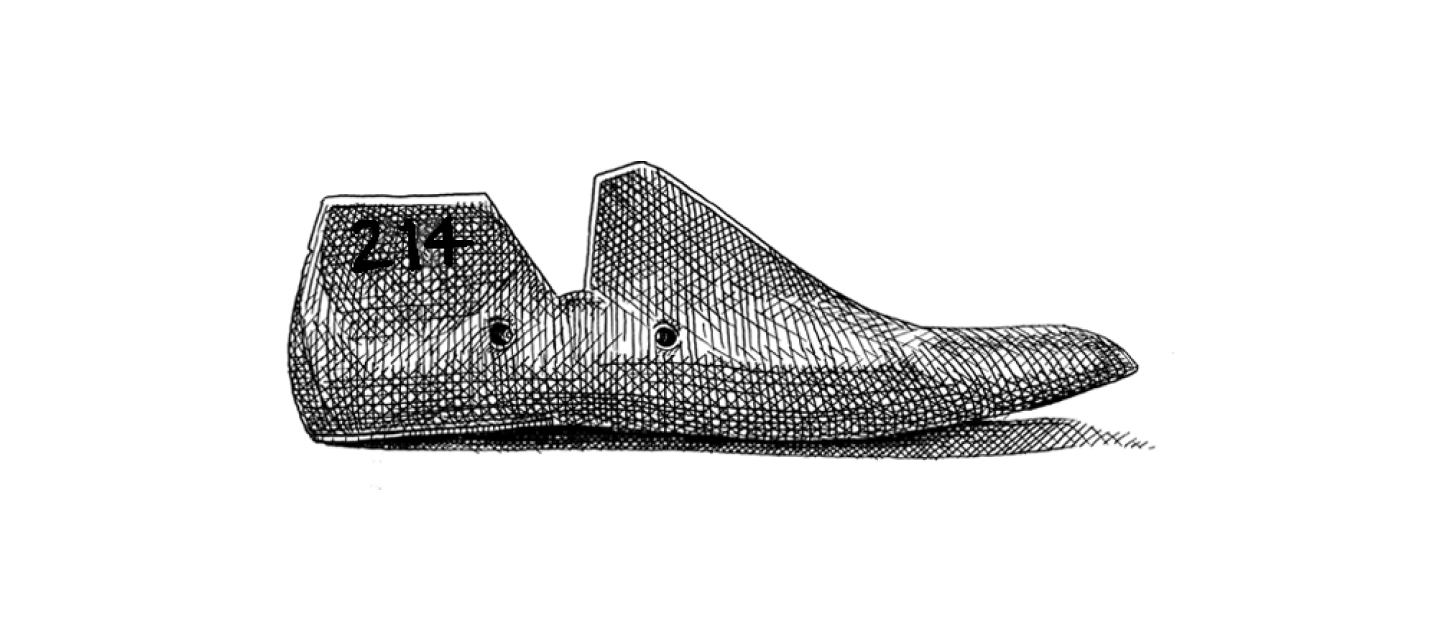

Lastmaking

The intricate process of last-making is the foundation of handmade shoemaking, where expert craftsmanship creates a custom mold to achieve the perfect silhouette for each shoe. The last serves as the form upon which we build the shoes, giving them their distinctive shape and character. The aesthetic sensibility of the last-maker plays a crucial role in defining the "house signature." Each of our lasts is carefully developed by hand by our in-house last-maker, utilizing the knowledge gained from our bespoke shoemaking heritage. These lasts are unique to Foster & Son, ensuring that our creations maintain an unmatched standard of quality, design and fit.

Pattern Making

Pattern making is the meticulous art of designing each shoe style, ensuring perfect proportions. We begin by taping our lasts and sketching the design directly onto them. Once we are satisfied with the design, it is translated into a two-dimensional template that serves as a guide for cutting the leather.

Selecting the leather

Selecting the leather is a crucial step in shoemaking. We carefully choose only the finest premium hides, considering factors such as texture, durability, comfort, and appearance to ensure the highest quality and longevity for each pair of shoes

Clicking

Clicking is the process of cutting out the leather pieces that form the upper parts of a shoe. It requires great skill and precision, as the "clicker" (the craftsman performing the task) carefully selects the best sections of the skin, paying close attention to the unique stretch of the leather and avoiding any imperfections. The clicker then cuts the leather into exact shapes using a sharp knife or cutting tool.

Closing

The process of assembling and stitching the various cut pieces of leather creates the shoe's upper. This step involves precise stitching, skiving, and attaching linings and decorative details, such as brogueing. The craftsman, known as a "closer," ensures that each stitch is both neat and robust, designed to withstand decades of wear.

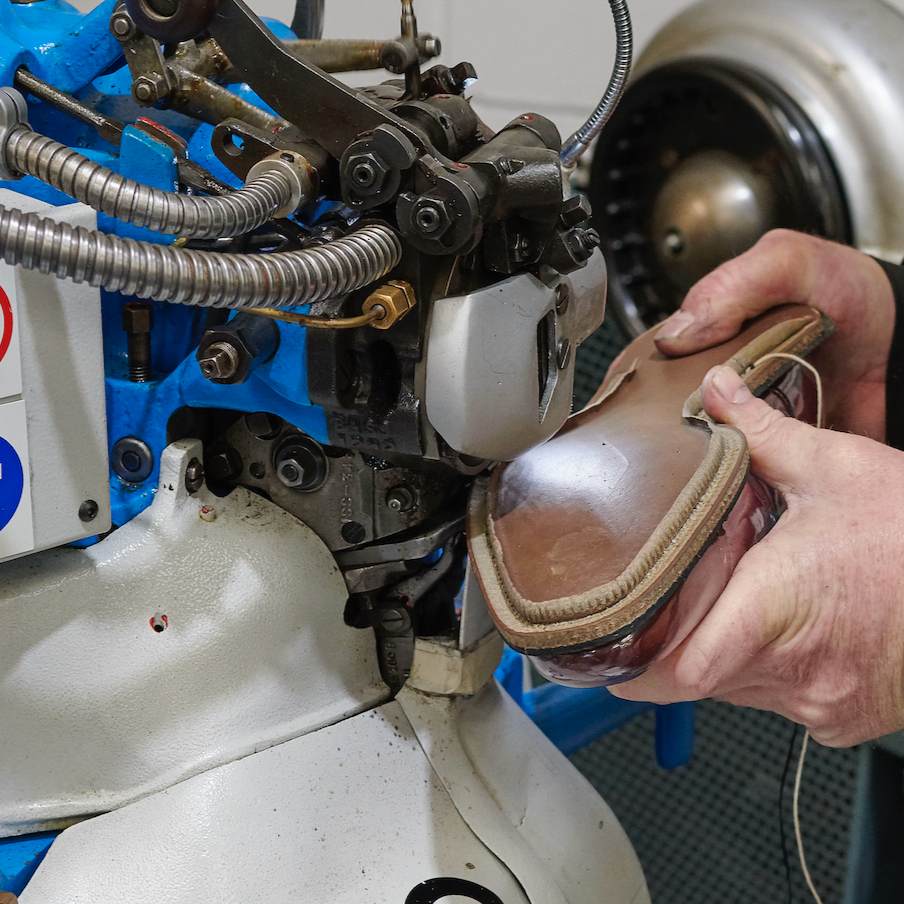

Goodyear welt

The Goodyear welting process is a traditional high-quality shoemaking method celebrated for its durability and the benefit of allowing the shoe to be resoled multiple times, thereby extending its lifespan. This technique involves stitching a leather strip, known as a welt, to both the upper and the insole of the shoe. Once the welt is attached, the cavity is filled with cork, providing cushioning and enabling the shoe to mold to the wearer’s foot over time. A shank is then placed at the waist to add rigidity under the arch. With the welt securely fastened between the upper leather and insole, the outsole can finally be stitched onto the welt.

Sole

The outsole, made from oak bark-tanned leather or rubber, is then stitched to the welt without penetrating the insole. This method makes the shoes easily resoleable, enhancing their longevity. This process requires highly skilled craftsmanship and is still regarded as one of the finest methods of shoe construction today.

Final polish and finish

After the shoe is fully constructed, the finisher carefully applies pigmented creams and waxes in layers, working them into the leather by hand to achieve the desired sheen and colour depth. This step involves gradual buffing to work the wax into the grain, enhancing the natural texture and patina of the leather. The final finish may include edge dressing and sole polishing to ensure every detail is flawless. This process not only gives the shoe a refined, polished appearance but also provides protection and longevity to the leather.